Welcome to Vertical Tooling

Delapena Honing Equipment manufactures a complete range of Vertical Honing heads and consumable tooling to suit most vertical honing applications, bore diameters and

lengths. Standard vertical tooling has a diameter range of 25.4mm (1.00") to 762mm (30.00") and is supported by a comprehensive range of standard,

Diamond and CBN abrasives.Overview

Delapena Honing Equipment designed and developed the range of vertical honing heads in conjunction with the development of the Beamstroker, Autostroker, Portable

Tooling & Powerhone. The vertical tooling range is ideal for the honing of bulky and heavy components that cannot be honed through conventional horizontal honing.The positive feed design ensures:

- Efficient correction of bore irregularities

- Combines excellent stock removal rates

- Precision and repeatable honing

- High quality surface finishes

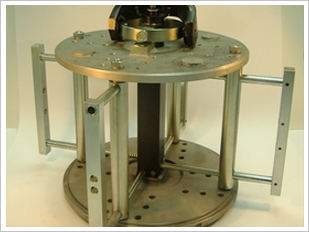

Automatic Feed Unit

The Delapena 1302 automatic feed system has been developed for use with the Powerhone vertical honing machine. The automatic feed unit is controlled by an operator

console that includes a selector switch for expansion or retraction. This enables the operator to apply the feed as required or to override the programmed pulse

settings.Friction Feed Unit

The Delapena 1301 friction feed system enables stone expansion and retraction to be remotely controlled while the hone head is rotating within the bore. The friction

feed system can be used with any power source, i.e. portable drills, pillar or radial arm drill, boring machines. Expansion of the hone head is applied by holding

the larger of the hand wheels. Retraction of the hone head is applied by holding the smaller of the hand wheels.Drive shafts

Delapena manufactures a complete range of drive shafts for use with the automatic and friction feed units. Standard driveshaft lengths range from 356mm - 864mm

(13"- 34"). Special length drive shafts can be manufactured upon request.Hone Heads

Delapena manufactures a range of hone heads that can be expanded manually or automatically. Hone heads come in a range of standard sizes from 25.4mm - 673mm

(1.0” - 26.5”). Double length hone heads are also available 63.5mm - 762mm (2.4" - 30.0"). This range is covered by just six (6) different hone

heads and auxiliary equipment. All manual hone heads are supplied with an extension shaft and drive shank for use in portable applications and on non-standard honing

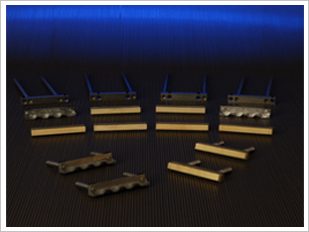

machines, for example drills, air driven nut-runners, pillar drills, milling machines and centre lathes.Stone Sets

Honing stone sets are either made up of 2 honing stones and 2 guides or 4 honing stones.2 Stone and 2 guide stone sets are most commonly used on distorted bores as well as helping considerably in the elimination of chatter. Honing guides are supplied in three different forms to ensure correct wear ratios are maintained between abrasives and guides.

4 stone sets are more commonly used in bores which require extremely close tolerances for roundness.

Stone sets are supplied in a wide range of Standard, Diamond and CBN abrasives to ensure that your required surface finish is achieved.

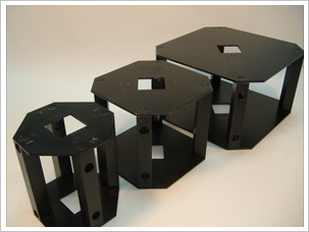

Stone Carriers and Supports

Stone carriers and supports are integral components in the Vertical Tooling range. They provide additional support and stability for larger diameter components.

Delapena standard stone carriers support a diameter range from 95.2mm - 762.0mm (3.75" - 30.0"). Stone Supports are required for all diameters beyond 158.7mm

(6.25") to provide additional rigidity and support during the honing process |

|

|

|

|

|